- Home Page

- Company Profile

-

Our Products

- NICU Products

- Monitor

- Patient monitor

- Hospital Garments

- BEST QUALITY HOSPITAL BLANKET

- Electro Surgical Generator

- Hospital Bedsheet

- Hospital Blanket

- Staff Uniform

- Hospital Staff Uniform

- Surgeon Gown

- Ot Gown

- MEN PANT OR SHIRT

- Patient Dress

- Girls Pant or shirt

- Hospital Bedsheet Single bed

- Best Quality Hospital Bedsheet

- Hospital Curtain

- HOSPITAL Curtain

- Polar blanket

- SCRUB SUIT/ NURSE DRESS

- BI-PAP Machines

- SYRINGE PUMP AND INFUSION PUMP

- Fluid And Blood Warmer

- AIR-Oxygen Blender

- ICU EQUIPMENTS

- Kongsung patient monitor

- DRAGER SEVOFLURANE

- DVT PUMP

- DRAGER OXYLOG 3000

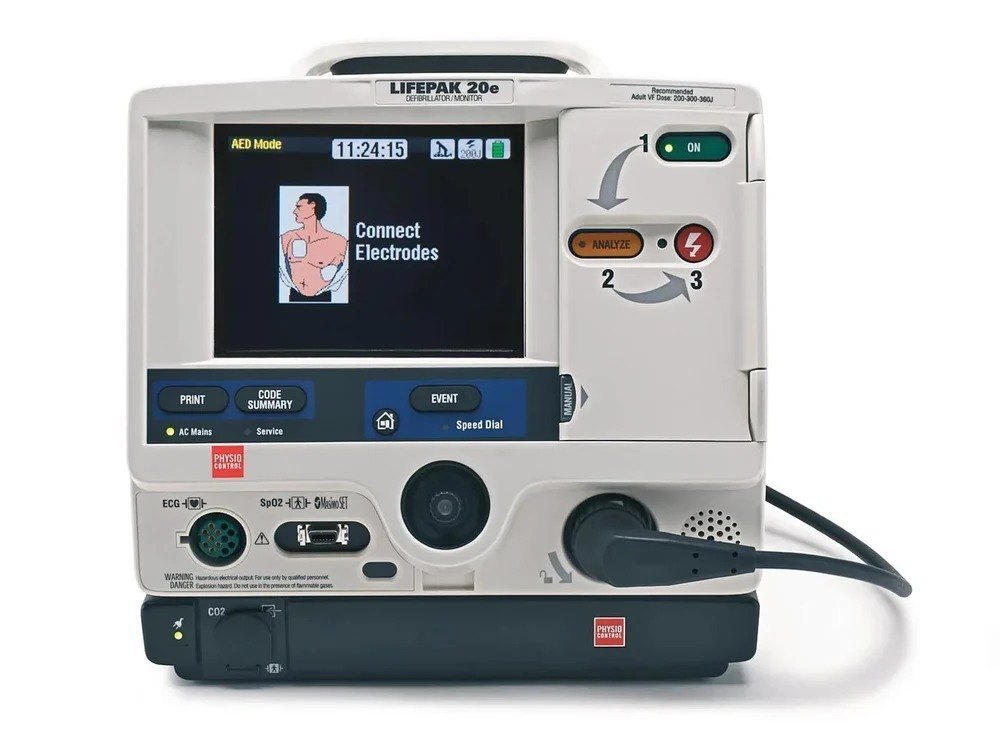

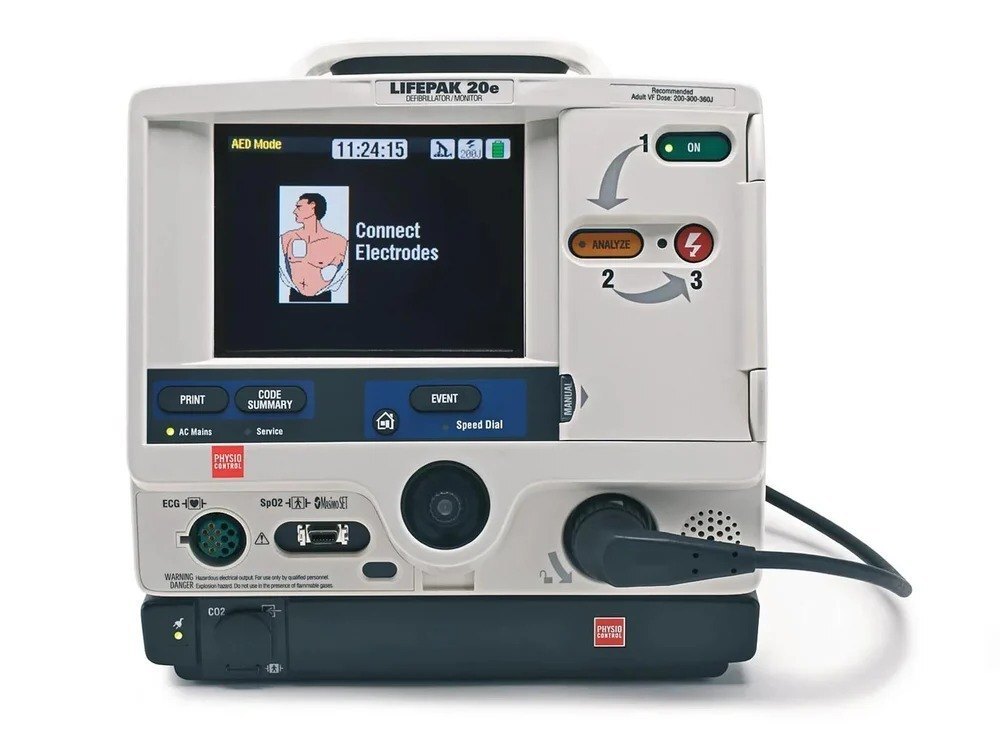

- MADTRONIC LP 20

- PHILIPS DFM 100

- PHYSIO CONTROL LP 9

- PHILIPS V 200

- VENTMED BIPAP DS8

- YONKAR SP 01

- DRAGER DESFLURANE

- DRAGER ISOFLURANE

- DRAGER HALOTHANE

- CONTEC IBP MODULE

- BREAS NIPPY 3, 3+

- PHILIPS TRILOGY 100

- PHILIPS EV 300

- PHILIPS HSXL

- COMEN NF 5

- HP CODE MASTER XL , XL+

- PHILIPS AED FR2

- PIGEON BLENDER DUAL FLOW METER

- AVI transport ENQUBATOR

- TRANSPORT VENTILATOR

- ICU ventilartor

- ICU VENTILATOR

- Drager Savina Ventilator

- MAQUET SERVO I VENTILATOR

- NELLCOR PURITAN BENNET LP 10

- Maquet Servo I Ventilator

- DRAGER SAVINA VENTILATOR

- Drager Evita 4 Edition Ventilator

- AVI AVIA 1.O

- Medtronic 5348 Single Channel

- Medtronic 5388 Dual Channel

- Portable Ventilator Ltv 950

- MAQUET SERVO I VENTILATOR

- SARVO i & S

- ECG

- CTG Machine

- Patient Monitor

- Philips Module

- Pulse Oximeter

- Extension Cable

- BABY PAC

- CPAP

- medical accessories

- NEONTAL TEST LUNG

- BUBBLE CPAP GENERTOR

- SINGLE HEATED CIRCUIT 101

- LTV 1200 KEYPAD

- VERSMED VENTILATOR CIRCUIT

- LTV COMPATABLE CIRCUIT

- SEMI AUTOMATIC HUMDIFIER HEATER WIRE CABLE

- MAQUET SERVO I VENTILATOR TROLLEY

- SIEMENS , VERSAMED O2 CELL

- PIGEON HUMDIFIER CHAMBER

- NEONATAL CARD AND ACCESSORIES

- BUBBLE CPAP KIT

- LTV 950/1000 KEYPAD

- DRAGER OXYLOG VENTILATOR CIRCUIT

- MR 850 ACCESSORIES

- BISTOS FETAL MONITOR ACCESSORIES

- PIGEON BLENDER ACCESSORIES

- YONKER SYRING PUMP CLAMB

- PIGEON SEMI AUTOMATIC HUMDIFIER TEMP PROBE

- DRAGER BABY LOG NEONTAL FLOW SENSOR

- ADULT BREATHING BAG

- ADULT ICU NIBP CUFF

- PHILLIPS DEFIBRILLATOR XL PADDLES

- PHILLIPS HEART XL INTERNAL PADDLE REFURB ORIGINAL

- PIGEON HIGH FLOW METER 60LPM

- LTV ORIGINAL ADAPTER

- HFNC CIRCUIT, FOR ICU

- VG 70 BETTERY

- FISHER AND PACKER

- SILICONE PEDITRIC AMBU BAG

- PHILLIPS HEARTSTART Xl BATTERY

- FLEXICARE SINGLE HEATED NEONTAL CIRCUIT

- HME + BV FILTER

- MBS DUAL WATER TRAP CIRCUIT

- MAQUET SERVO I O2 CELL

- CONTEC DUAL IBP MODULE NEW

- DRAEGER EVITA POWER SUPPLY

- LP10 VENTILATOR CIRCUIT

- Air and O2 Mixer - Drager Evita

- Nibp Hose Pipe

- ADULT SPO2 PROBES

- PEDIATRIC TEMPREATURE PROBE

- MONITOR EARTHING CABLE

- ECG CABLE COMBITABLE

- Ecg Cables And Accessories

- PVC Heated LP10 VENTILATOR OXYGEN KIT

- HONEYWELL O2 Cell

- 2 LITER BAG BALLON

- DRAGER EVITA FUNCTION BOARD

- DRAGER 02 SENSOR

- ECG Electrodes Silver

- Disposbale Anesthesia ventilator circuit adult

- N-600/595 NELLCORE KEYPAD

- 6 Pin 3 Lead / 5 Lead , Clip Type / Snap Type Multi-para Monitor ECG Cable

- Nellcor Spo2 Extension Cable

- Masimo Radical-7 Adult Soft Rubber Type Spo2 Sensor

- Contec Spo2 Sensor

- TruSat Peadiatric finger clip Type Spo2 Sensor

- Adult Finger Clip Type Spo2 Sensor

- Phillips 12 Pin 3 Lead / 5 Lead ,Neonate Clip Type / Neonate Snap Type ECG Multi-para Monitor Cable

- Holter Ecg Cable for Contec TLC5000

- Ecg Silicone Bulbs Electrodes Multi Color and Blue - Adult / Pediatric Indian / Imported

- PHILLIPS 10 LEAD ECG PATIENT CABLE - 4 MM BANANA - 22K.R ECG Cable

- DRAGER O2 CELL

- Disposable Heated Wire Adult ventilator circuit with Chamber - Adult / Neonatel

- LTV ORIGINAL CIRCUIT

- VERSA MED CIRCUIT

- Disposable Ventilator Circuit Adult LP10

- TRILOGY CIRCUIT

- OXYLOG 2000/3000 CIRCUIT, For ICU Use

- Reusable Ventilator Circuit Double Water Trap Double Limb - Adult / Pediatric / Neonatel

- AUTO FEED DISPOSABLE CHAMBER

- LTV 1000 KEYPAD

- NIPPY KEYPAD

- Contact Us

MADTRONIC LP 20

1 INR/Piece

Product Details:

- Application Liquid Packaging

- Suitable For Milk, Juice, Water, Oil

- Frequency 50 Hz

- Power 1.5 kW

- Material Stainless Steel

- Shape Rectangular

- Product Type Liquid Packing Machine

- Click to View more

X

MADTRONIC LP 20 Price And Quantity

- 1 INR/Piece

- 10 Piece

MADTRONIC LP 20 Product Specifications

- LCD

- 220 V

- Robust Construction, High Efficiency

- 5C to 50C

- Silver

- Filling & Sealing

- Automatic

- 1700 mm

- Liquid Packing Machine

- Rectangular

- Stainless Steel

- 1.5 kW

- 50 Hz

- Milk, Juice, Water, Oil

- Liquid Packaging

- Single

- 250 kg

- Packing and Sealing Liquid

- High

- Digital

- 750 x 550 x 1700 mm

- Automatic Liquid Packaging

- Electric

MADTRONIC LP 20 Trade Information

- INR

- Cash Advance (CA)

- 10 Piece Per Day

- 3 Days

- Yes

- Sample costs shipping and taxes has to be paid by the buyer

- box packing

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- All India

Product Description

A complete packageTo deliver high levels of care, you need to make quick, informed decisions at the scene of an emergency and across the entire course of treatment. You need your equipment to be easy to use as you care for a patient, monitor developments in the patient's condition during transport to the hospital, and as you care for your patient in the hospital.Unique advantages

The Efficia DFM100 defibrillator/monitor is designed to help you meet the demands of patient care in the pre-hospital and hospital environment. With field-proven Philips technology, the Efficia DFM100 offers core functionality with a scalable feature set and improved cost of ownership, allowing you to enhance patient care, wherever the patient is located.

Advanced Liquid Packing Solution

MADTRONIC LP 20 specializes in efficient and precise liquid filling and sealing. Suitable for milk, juice, water, and oil, this machine streamlines your packaging process by handling up to 2000 pouches per hour with excellent accuracy. The PLC control system and LCD display make it user-friendly and reliable for businesses of all sizes.

Robust Construction & User-Friendly Design

Crafted from stainless steel, the LP 20 ensures lasting durability and hygiene. Its compact dimensions allow for easy integration into various indoor production settings. The automatic filling and sealing functions empower businesses to boost productivity with minimal manual intervention, reducing operational costs.

FAQ's of MADTRONIC LP 20:

Q: How does the MADTRONIC LP 20 improve the liquid packaging process?

A: The LP 20 automates the filling and sealing of pouches, significantly increasing packaging speed and consistency. With its PLC control and high-accuracy sensors, it minimizes human error, enhances output quality, and supports continuous operation for up to 2000 pouches per hour.Q: What types of liquids can be packaged with the LP 20, and what are the suitable pouch sizes?

A: This machine is ideal for milk, juice, water, and oil. It accommodates pouches with widths from 50 to 150 mm, lengths from 50 to 200 mm, and filling volumes between 50 to 500 ml, making it highly versatile for various product lines.Q: When is maintenance required for the LP 20, and how is it performed?

A: Regular maintenance is recommended after every production cycle or as specified in the user manual. The stainless steel construction simplifies cleaning, and lubricating moving parts as well as checking air and electrical connections ensure optimal performance.Q: Where should the MADTRONIC LP 20 be installed for best performance?

A: The LP 20 is designed for indoor use and should be placed in a clean, dry environment with access to electric (220V, 50Hz) and compressed air (0.6 MPa) supply. Adequate ventilation and space are also important for safe and efficient operation.Q: What benefits does the PLC control system provide for users?

A: PLC control offers automated monitoring and adjustment of machine parameters, resulting in precision filling, reduced downtime, and improved safety. Users benefit from the easy-to-use LCD display which simplifies machine setup and operation.Q: How is the sealing process executed, and what type is used?

A: The LP 20 employs a center seal mechanism, which securely bonds the pouch edges for effective leak prevention. The temperature range of 5C to 50C and digital accuracy ensure strong and uniform sealing, suitable for various liquid products.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send SMS

Send SMS Call Me Free

Call Me Free